Train Room Shell

The Home and Design of the RGW

Train Room (Shell)

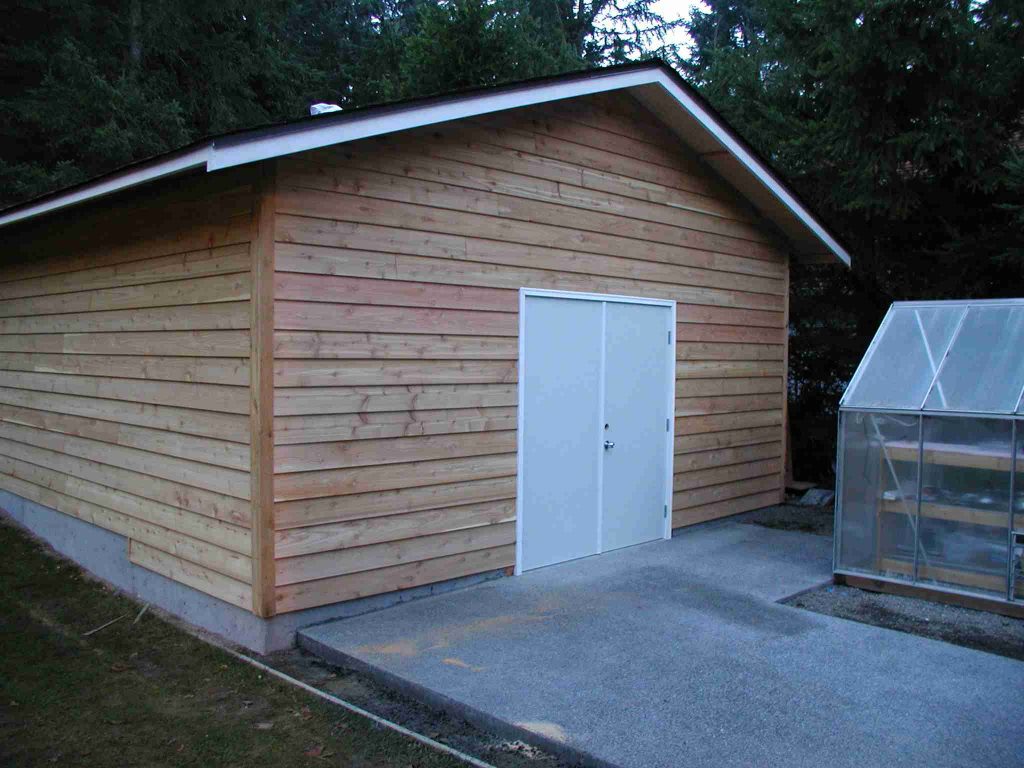

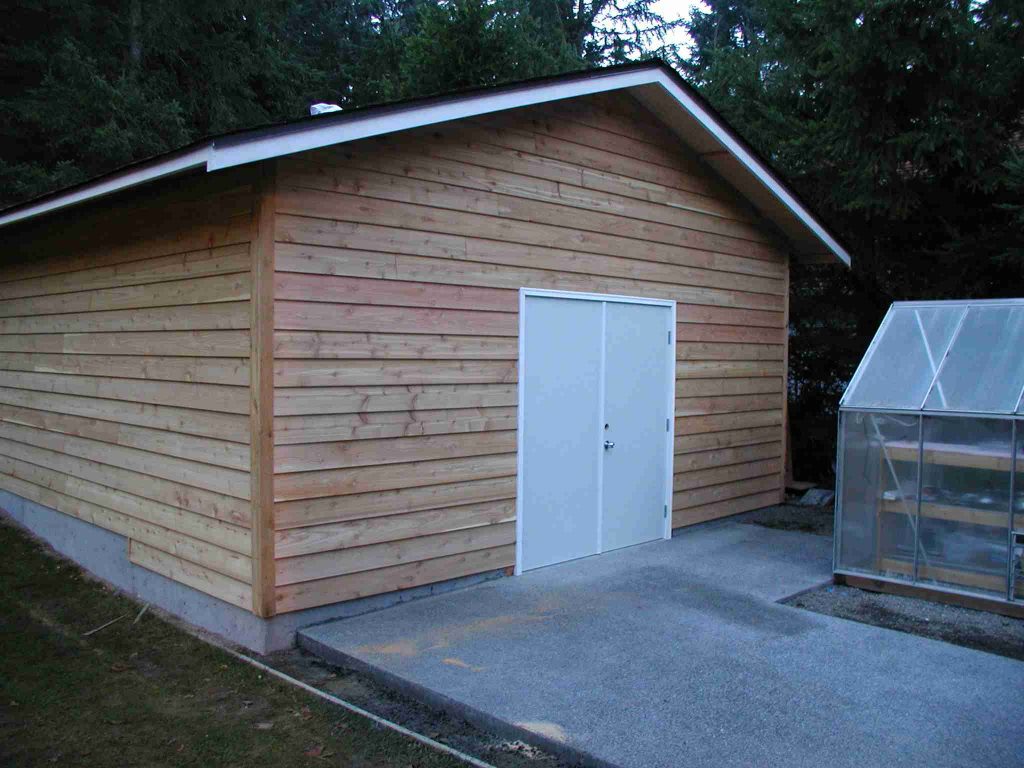

Final Exterior Dimensions 20' x 30'

The Train Room Build

The Before - A Big

Toy

We decided early on that the big toy was an extra and a review of the CCR’s for the development told us we could construct the train room, as long as it resembled the main structure.

Stage One - Lumber Package

The lumber package was delivered shortly after the initial sitework was completed. The delivery from Gray Lumber in Tacoma marked the first real sign a building was going to be built.

Stage Two - Forms and Dirt

Construction crews brought in a bobcat and started to excavate the site. Due to the slope, it was determined that the floor would need at least one step to minimize the total amount of dirt removed. The lumber package was broken down, forms were laid and the first concrete poured.

Stage Three - Framing Begins

While the bobcat remained to complete the final preparation of the sitework, the framing of the building began and the train room started to take the shape of a real building.

Stage Four - Framing Speed

Once the bobcat completed the sitework, the framing really hit stride and soon thereafter the trusses and sheathing were delivered to give the building a true definition.

The Before - A Big Toy

We decided early on that the big toy was an extra and a review of the CCR’s for the development told us we could construct the train room, as long as it resembled the main structure.

Stage One - Lumber Package

The lumber package was delivered shortly after the initial sitework was completed. The delivery from Gray Lumber in Tacoma marked the first real sign a building was going to be built.

Stage Two - Forms and Dirt

Construction crews brought in a bobcat and started to excavate the site. Due to the slope, it was determined that the floor would need at least one step to minimize the total amount of dirt removed. The lumber package was broken down, forms were laid and the first concrete poured.

Stage Three - Framing Begins

While the bobcat remained to complete the final preparation of the sitework, the framing of the building began and the train room started to take the shape of a real building.

Stage Four - Framing Speed

Once the bobcat completed the sitework, the framing really hit stride and soon thereafter the trusses and sheathing were delivered to give the building a true definition.

Stage Five - Sheathing

Once the rough framing was complete, the sheathing went up quickly. Here men from Summit Central Construction prep the roof for trusses.

Stage Six - A Building

With the roof trusses on, the siding and roofing could be put in. It was decided that two solatubes would be placed in the front part of the building to provide some light in daylight hours and reduce dependence on incandescents.

Stage Seven - Concrete

The arrival of the concrete pumper signalled the move inside the building. With the electrical run from the main house to the train room, it was time to pour the floor and the pad at the entry.

Stage Eight - Concrete Floats

Three members of the SCCI crew put the finishing touches on the concrete floor. You can see the step inside the room that was necessary to compensate for the exterior slope.

Stage Nine - A Train Room

The concrete poured and hardened, the front of the structure was given siding and steel doors. The pad in front of the building was left as exposed aggregate to match existing sidewalks.

Stage Five - Sheathing

Once the rough framing was complete, the sheathing went up quickly. Here men from Summit Central Construction prep the roof for trusses.

Stage Six - A Building

With the roof trusses on, the siding and roofing could be put in. It was decided that two solatubes would be placed in the front part of the building to provide some light in daylight hours and reduce dependence on incandescents.

Stage Seven - Concrete

The arrival of the concrete pumper signalled the move inside the building. With the electrical run from the main house to the train room, it was time to pour the floor and the pad at the entry.

Stage Eight - Concrete Floats

Three members of the SCCI crew put the finishing touches on the concrete floor. You can see the step inside the room that was necessary to compensate for the exterior slope.

Stage Nine - A Train Room

The concrete poured and hardened, the front of the structure was given siding and steel doors. The pad in front of the building was left as exposed aggregate to match existing sidewalks.